Module 2

Focus on the industry standards and the GS1 symbologies

Go Back to

the Main Menu

Axicon are committed to designing and manufacturing

verifiers which meet all of the appropriate standards.

But just what are these standards ? In this module we attempt to cover the essential elements of the compliance issues.

First we will identify the standards we refer to and how they

interact together, then we will explain in more details how Axicon

complies with these various standards.

1. How the

various standards interact

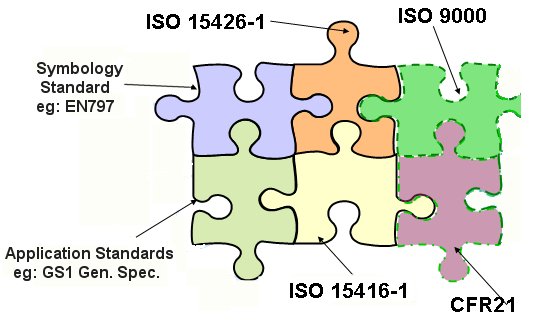

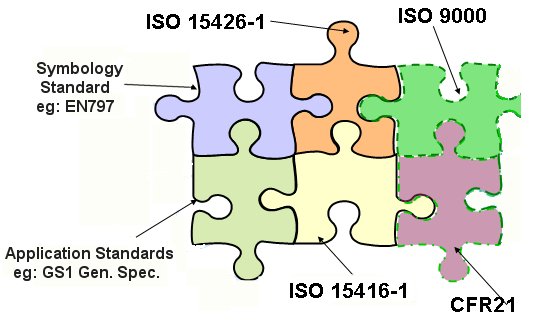

These standards do not work in isolation from each other but rather fit together like a jigsaw

puzzle, as inter-relating elements, as described in the drawing below:

1-1:

The Symbology Specifications Standards

1-1-1 Introduction

Each “Symbology” is a machine readable typeface controlled by clear specifications as to how each human-readable character should be

encoded, along with the permitted tolerance limit, and the measurements which need to be taken to ensure that the

symbol is readable.

If we are going to choose to use a particular barcode symbology, then we

must print the code correctly if we want it to be scannable.

The tolerance limits are not ours to decide and failure to comply with the print quality requirements will degrade the scannability of the code.

The issues involved here are:

The most commonly referred to Symbology Specifications are

EN 797 Barcode – Symbology Specification - "EAN/UPC"

EN 798 Barcode – Symbology Specification - "Codabar"

EN 799 Barcode – Symbology Specification - "Code 128"

EN 800 Barcode – Symbology Specification - "Code 39"

EN 801 Barcode – Symbology Specification - "Interleaved 2 to 5 / ITF"

1-1-2 Focus on some GS1

symbologies

This chapter will be an introduction to

some of the GS1 most used symbols. The information is rather minimal.

The aim is to emphasize some characteristics of the barcodes

construction or data structure that will play a role in the quality

control of the symbols.

EAN-13

The EAN-13 barcode is one of the

EAN/UPC symbologies and it is arguably the most widely used throughout

the world to mark retail products that are scanned at points of sale.

The diagram below shows an image of an EAN-13 barcode. The human

readable data is written under the barcode i.e the machine readable

data.

On both sides of the barcode, the light

margins (also called Quiet Zones) are the areas left free of any

marking to guarantee that nothing is going to be in the way of the

reader when it scans the barcode so that there is no confusion as to

where the barcode starts and ends. The first digit in the human readable

and the indicator at its right can be used to give a

physical indication of the minimal width required for the light

margins.

The guard bars are used to

structure the barcode. They consist of a set of bar/space/bar at the

start and the end of the barcode and a sequence of

space/bar/space/bar/space right in the middle of the barcode. The rest

of the bars and spaces encode the digits of the code according

to a set of rules we will now explain in a simple

way.

Looking carefully at

examples of EAN-13 you will notice that it has four possible different

widths of bars and spaces. All the bars and spaces are in fact built

on the base of the smallest bar also called the X dimension or the

nominal bar such as the first bar at the start of the code. Each bar

in the code has either the same width, twice the width or three or

even four times the width of the nominal bar. This is also true for

the spaces. An EAN-13 barcode is therefore a sequence of bars and

spaces of different width (1 to 4). Two different EAN-13 barcodes will

have the same amount of bars and spaces but the width of these bars

and spaces will be different because they encode different numbers.

The table below gives the

modular structure of the EAN-13 encodation for each of the ten digits

from 0 to 9. There are three possibilities (sets A, B & C) for

each digit. The set C is always used in the right half of the barcode,

for the last 6 digits of the code, encoded at the right of the middle

guard bars. For the left part of the barcode, things are a little

different. As a matter of fact the first digit, 5 in the example

above, is not encoded by bars and spaces. The 6 digits from the second

digit to the 7th only are encoded, either in Set A or in Set B. The

lead digit is then deducted from the sequence of A or B used.

The Modular structure

table here above is a useful tool to understand how an EAN-13 barcode

is constructed.

In the diagram below, we

have zoomed on the digit 0 in Set C, it is

represented by a bar of 3 modules then a space of 2 modules then a bar

of 1 module and a space of 1 module. The structure B3/S2/B1/S1 that is

indicated in the table can be easily spotted in the barcode too, where

the last "0" of the code is encoded. Using the modular

structure table (and a magnifying glass!) you could easily read any barcode that

is printed well enough.

ITF-14

The ITF-14

barcode is used to mark outer cases handled in logistic operations

which do not get scanned at the till. This symbol has also got a

specific structure, with guard bars at the start and the end of the

barcode, left and right light margins. Here there are only two

different width of bars and spaces. The smallest bar (the X dimension)

is called the narrow bar. The wide bar is related to the narrow bar by

a ratio that is generally of 2.5, so the wide bar has 2.5 times the

width of the narrow bar. This is also true for the spaces. Very often

the ITF-14 barcode is framed by what is called the Bearer Box. This is

used to avoid short reading of the barcode and to even the pressure

over the barcode for some printing processes.

EAN/UCC-128

The EAN/UCC-128 symbol is used to mark

outer cases (it is mandatory when the product shelf life is less than

42 days) and also for pallet labels. As per the EAN-13, the structure

is modular, with 4 different width of bars and spaces, but here the

modular structure is completely different to the structure of the

EAN-13.

EAN/UCC-128 is in fact a subset of the

Code 128 symbology. It is identified by the use of a lead character

called the Function 1 character, encoded straight after the start

character. This symbol is of a variable length and the data is

organised by Application Identifiers (AIs). In the example below, both

AIs 01 and 15 are used. AI 01 encodes a 14 digit long code that

represents the Global Trade Item Number of the product and the AI 15

encode the best before date for this product, displayed by 6 digits on

the format YYMMDD (25 December 2006 in the example below). There is an

exhaustive list of AIs in the GS1 Genspec for all sorts of

applications. When one checks the quality of an EAN-128, it is not

just the print quality that is verified but also the conformity of the

data structure.

1-2:

The ISO/IEC 15416-1 Standard

ISO 15416-1 "barcode print quality test specification - part 1 linear symbols".

This standard specifies the method by witch we measure the quality of a printed linear

barcode. It applies to those symbologies for which a

reference decode algorithm has been defined and which are intended to

be read using linear scanning methods.

The

method for assessing the print quality of the barcode is based on

measuring the diffuse reflectivity of the barcode and its substrate

along a number of scan paths which shall traverse the full width of

the symbol, including both quiet zones. This is done according to a

given optical arrangement, measuring aperture and peak light

wavelength (See comments). A scan reflectance profile is extracted and

analysed to measure several parameters which are then graded. The

overall symbol grade is then calculated and reported using the form: Grade/Aperture/Wavelength.

e.g 4.0/06/660.

Comments:

1/

EN 1635 and ANSI X3.182 are the European and American equivalent

of ISO 15416-1 (the main difference with ANSI is the A-F grading as opposed to 4-0 in ISO and CEN)

2/

In chapter 5.1, Measurement requirement, the standard specifies that

the measurements shall be made with a single light wavelength and

measurement aperture of a diameter defined by the application standard

or if unavailable determined in accordance with chapter 5.2.1 and

5.2.2 of the ISO standard. This is a perfect example of how the

standards interact, here the ISO recognises that for specific

measurements parameters like the aperture or the light wavelength, the

application standards should overrule the ISO specifications.

1-3:

The ISO 15426-1 Standard

ISO 15426-1 " barcode verifier conformance specification - part 1 linear symbols"

This refers to the actual equipment used to perform the ISO 15416-1 method of verification.

This standard lists the mandatory functions that a conforming verifier must be capable

to perform.

It also specifies the tolerances which must be met when measuring Primary Reference Test Symbols

1-4:

The Application Standards These

standards

are specific to each industry and given application. The most common one being the

Genspec,

as in the GS1 General Specifications. This is the “Application Specification” which controls

all barcodes within the retail supply chain. It specifies

all factors such as: barcode symbology or mandatory

requirements for each application, barcode size for each application,

bar height, location and orientation of the code on the product, minimum

acceptable quality grade, wavelength of light and aperture size to be used to measure the

code...

Other Application Standards:

CFR 21 is an “Total Audit Traceability” requirement within the pharmaceutical industry.

Spec 2000 is for the aerospace industry

NDC 2001 is an EAN/UPC National Drug Code.

EN 1573: Transport industry

1-5/ How do these standards interact ?

What is important to understand is that these 4 families of standards all interact. Example : If

you verify an EAN-13 barcode applied on a product sold in a supermarket

you then have to comply to:

Genspec: because this is sold at a retailers point of sale. This is what will define the minimum C grade pass note, the verifier’s aperture (150 microns) and wavelength (670nm +/-10) the allowed magnification (80 to 200%), the light

margins (11X Left Margin, 7X right Margin), etc...

EN797: Because it is an EAN/UPC barcode. That is where the

reference decode algorithm is specified, the control character, the

structure...

ISO-15416 et ISO-15426 Because as specified in the Genspec, this is the method you are supposed to use to grade

the print quality level of the barcode.

2.

How to setup & use your Axicon verifier to comply with these standards

2-1:

Compliance to the symbology specifications

The reference decode algorithms specified in the symbology

specifications are used by the Axicon verifier for the relevant symbols, hence

the Axicon verifier software complies with the following symbology

specifications:

EN 797 Barcode – Symbology Specification - "EAN/UPC"

EN 798 Barcode – Symbology Specification - "Codabar"

EN 799 Barcode – Symbology Specification - "Code 128"

EN 800 Barcode – Symbology Specification - "Code 39"

EN 801 Barcode – Symbology Specification - "Interleaved 2 to 5 / ITF"

2-2:

Compliance to ISO 15416-1

Compliance to the ISO/IEC 15416-1 standard is achieved by using the

specified optical arrangement to analyse the diffused light

reflectivity and by calculating the relevant parameters from the

reflectance profile.

2-3:

Compliance to ISO 15426-1

Independent tests have been carried out and Axicon Series 6000, 6500

and 7000 have been certified to comply with the ISO 15426-1 standard.

To comply with this standard the verifier must perform a list of

function (established in chapter 6.3) and provide accurate results, with

certain tolerances, when scanning reference test cards.

2-4:

Compliance to the Application Standards

2-4-1 About the GS1 General Specifications (Genspec)

Most of today's users of barcode quality control equipment are

involved in the retail supply chain, where the Genspec application

standard, promoted by GS1, is the reference guide for all matters

relating to the barcoding best practice. This standard is also being

used more and more outside the retail supply chain, particularly for

healthcare applications. For that reason we have integrated into

our software the possibility to automatically check some of the Genspec

requirements that can be measured by a barcode verifier, like the

magnification. We have also taken into account within the settings those

parameters where the application standard over-rules the ISO 15416-1

standard, like the measuring aperture.

In the General tab of

the Setup window, you have the option to tick the Apply Genspec box.

By doing so, the minimum pass grade will be allocated as per the

Genspec rules. The table below summarises the Genspec requirements. For

more comprehensive information, please report to the Specification Tables, in

the Chapter 5.4 of the latest issue of the Genspec. Click

here for a link to Genspec Chapter 5.4

Summary table for the

main GS1 linear symbologies:

|

Symbology

|

Scanned

at/in:

|

Example

|

X dimension mm

|

Magnification

|

Minimum pass grade/Aperture

|

|

EAN/UPC

|

Point of

sales only

|

Bottle of water

|

[0.264 -

0.66]

|

[80% -

200%]*

|

1.5/10

|

|

EAN/UPC

|

Warehouse or POS

|

Pack of 6 bottles

|

[0.495 -

0.66]

|

[150% -

200%]

|

1.5/10

|

|

EAN-128

|

Warehouse

|

Tray of

fresh fruits

|

[0.495 - 1.016]

|

[48.7% - 100%]

|

1.5/10

|

|

EAN-128

|

Logistic operations

|

Pallet

label

|

[0.495 - 0.940]

|

[48.7% - 92.5%]

|

1.5/10

|

|

ITF-14

|

Warehouse

|

Outer case

|

[0.495 - 0.635[

[0.635 - 1.016]

|

[48.7% - 62.5%[

[62.5% - 100%]

|

1.5/10

0.5/20

|

* For an EAN/UPC barcode printed with an

on demand process ( e.g.. thermal transfer), the allowance goes down to

75%

Parameters

checked by the verifier: (displayed in the Summary Window):

-

ISO grade.

If the average grade is lower than the minimum pass grade for this

symbology (as per the table above) then a red flag will be

displayed If the average grade is above the minimum pass grade by

less than 0.5, a yellow flag will be displayed. Please note that

for EAN/UPC, ITF-14 and EAN-128 barcodes, the verification of the

light margins and the check character are part of the ISO grading

(Decode parameter).

-

Wide to Narrow Ratio (where

applicable): A red flag will be displayed if the ratio is outside

the specifications. For an ITF-14 barcode, the ratio is

tolerated between 2.25 and 3.

-

Barcode X

dimension (Magnification): If the X dimension is outside the Genspec

tolerance value shown in the table above, a red signal will be displayed. A

yellow signal will be displayed in the case of an EAN/UPC barcode

with a magnification between 75% and 80%.

Parameters

not checked by the verifier:

-

Bar height. The

specification are as follows: For a retail unit scanned at point

of sales, the minimum acceptable height is 20.73 mm (Including

human readable) and for a barcode read in warehouse/logistics

operation, 32 mm (Bar height only this time). Even though some

packagings do not leave enough room for such heights and it can be

agreed between trading partners to truncate the barcode further,

it should be noted that the readability of a barcode will be

highly affected by a too excessive truncation.

Comments:

1/ For anyone involved with printing or handling barcodes, compliance

to the Genspec is a process which takes several steps, some of which

can be carried out by the Axicon verifier. The table below is a

summary of these steps involved in checking barcode compliance to the

Genspec:

|

Level

|

Check

|

Done

by the verifier

|

Iso

Grading

|

|

1

|

Is the code correct

(right code on the right product)

Right Symbology used ?

Does the barcode match the human readable code?

Location / Orientation

Bar Height / Truncation

|

NO

|

NO

|

|

2

|

Size (Magnification)

/ Ratio

Bar Gain (no tolerance value specified in the Genspec)*

Data Conformity

|

YES

|

NO

|

|

3

|

Print Quality ISO Grade

- Decode

- Rmin

- Symbol Contrast

- Minimum Edge Contrast

- Modulation

- Defects

- Decodability

|

YES

|

YES

|

* The Average Bar Gain

check does not relate to the Genspec and does not get an ISO grade.

It's tolerance values are set in the Traditional Verification method.

It's mentioned here because it is relevant to the print quality

verification.

2/

The idea for presenting the table above is to show how compliance to

the GS1 General Specifications is not limited to obtaining a pass

ISO/ANSI grade. A barcode could fail the Genspec for size or bar

height but be well printed and obtain a satisfactory grade.

2-4-2 Compliance to

CFR-21 Part-11

This is so important essentially because many companies either in the pharmaceutical industry or as suppliers to pharmaceutical companies will insist on CFR21 Part 11 compliance before

allowing them to be an approved supplier.

Regarding CFR21 Part 11 the issues are generally as follows:-

a) Much of the requirement is on the features of the product – and here our software can be set-up in such a way as to ensure compliance.

This includes such things as ensuring that the equipment cannot be used after a pre-determined calibration period, ensuring that only valid calibration materials be used, ensuring that all scans made are timed and dated, that they are sequentially numbered, that full data (scn file) is recorded on calibration processes, that the name of the person taking the scan can be recorded (user name.avp) etc...

b) The second part of the process concerns product compliance with standards.

c) The final part relates to the design and manufacture of the product and manufacturing process control.

For a more detailed

information on how to setup the software to comply with CFR-21 Part

11, please contact Axicon.

DISCLAIMER

This document is intended as a recommendation of work practices sponsored by Axicon Auto ID Ltd. Whilst this document is believed to contain correct information, neither Axicon Auto ID Ltd nor any of it’s associated companies, nor any of it’s employees, make any warranty, express or implied, or assume any legal responsibility for the accuracy, completeness or usefulness of such information that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by its trade name, trademark, manufacturer or otherwise, does not necessarily constitute nor imply Axicon Auto ID Ltd endorsement nor recommendation. The views and opinions of authors expressed herein do not necessarily state or reflect those of Axicon Auto ID Ltd.

|