|

|

||||||||||||||||||||

Module 1

|

||||||||||||||||||||

|

Axicon 6500 Series & 7000 Series Place the verifier neatly over the surface of the barcode as per the illustration. Make sure the scan line is straight across the code. The scan line is about 10 mm from the front of the unit. Always close the hinged flap at the front of the unit. Press on one of the two switches on the top of the handle to trigger the scan.

|

|

|

||||||||||||

|

Axicon 6000 Series Place the verifier neatly over the surface of the barcode as per the first illustration on the left. Make sure that when possible, the 4 corners are in contact with the surface so that you minimise the possible influence of ambient light. Make sure the scan line is straight across the code. The scan line is about 3mm from the front of the unit. Press on the switch located underneath the handle to trigger the scan.

| ||||||||||||||

5.2 - Multi Scan Average

It is recommended to scan the barcode at different heights and average the results in order to give a more accurate overall grading. You can average up to 10 scans of the same barcode. The ISO 15416 standard in its chapter 5.2.5 recommends a minimum of ten scans but the number of scans may be reduced in order to simplify the process of assessment of a large numbers of symbols. The standards, in Annex J2, refer to a methodology based on results achieved on previous print runs of the same symbol. The amount to average over goes from 2 scans to 10 scans as the code goes from a consistently good barcode to a consistently defective barcode.

Tip: Take 3 scans of the barcode: one at the top, one in the middle and one at the bottom. If the results are good (A or B) and very consistent (same grade each scan) then a 3 scan average is enough, if the result are not so good (C, D or F) and not so consistent (1 grade difference) then use a 5 scan average, if the results are not consistent (results with 2 grade difference or more) then try a 10 scan average.

However, our experience shows that many companies specify a 10 scan average verification in their barcode quality control guidelines, so the 10 scan approach should be favoured if in doubt.

Comments:

1/ The Axicon verifier software allows you to average over up to 10 scans per barcode. This can be set up from the "Command" screen. The information on individual scans can be stored and displayed at any time, along with the average values.

2/ By only taking a single scan the symbol may be graded lower than it actually is.

Taking a single scan through a bad defect will produce a slightly 'unfair' assessment of the symbol, whereas taking several scans will produce a result which is more representative of scanning performance, which of course rarely occurs at just one height within the symbol.

2/ If the number of scans is set to "1",you do not need to clear the screen between scans, but if you average 2 scans or more, then when you have completed scanning for one code, you need to press the delete key to perform a refresh before scanning a new barcode.

5.3 - About

the ambient light

When we verify a printed barcode, we look at its physical properties independently from the environment particularly the ambient light. Ambient light at the scanning stage at the retailers cannot be anticipated and should not influence the results at the verification stage. The Axicon verifiers have been built to

minimize the influence of the ambient light as much as possible. If properly used, our verifiers cover most of the barcode, thus creating an enclosed area around the barcode.

However, there is still some minimal access for the ambient light. Also with some packaging, it is impossible to properly cover the scanning area and finally some shiny or even worse non opaque materials leave us with little chance to protect the scanning from the ambient light. So we recommend that you avoid scanning too closely or directly under a source of

light, particularly when scanning under sunlight, fluorescent light, high pressure sodium or mercury vapour lamps.

5.4 - Printing a verification report & Saving the data

Once you have verified a barcode, you have several options available. All the results are displayed over the various window of the verifier. You can then decide to ignore the scan and delete the data or you can print a verification report, which provides a summary of the relevant information including the ISO grading for all the required parameters, or you can save the data, which then allows you to open the file at a later stage to review the result on screen or to print a report. When you save the data, the results are saved on your computer or on your chosen media as a .SCN file that can later be opened on any PC/Mac which has the software loaded. When you open the file, all the data is displayed and can be printed off, as if you had just begun verifying the barcode.

This also enables you to ask for a remote diagnostic immediately (the file can be sent by email). The software can be set up to save all the scans automatically or this can be done manually as you scan. The manual saving allows you to retain only the important verifications and to provide an appropriate file name.

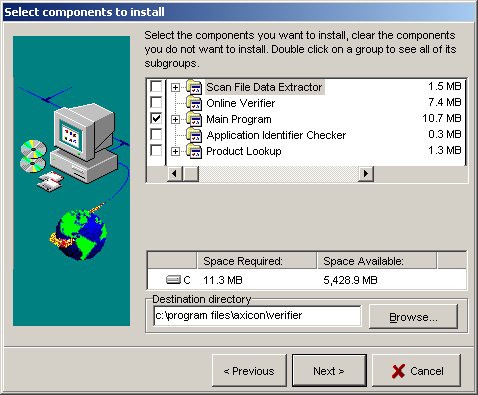

An optional program San File Data Extractor has been developed to be used in conjunction with

Axicon PC Verifier. This program allows you to select verification files in a table and is a useful tool for statistical analysis. See Technical Module 4 for more information.

Comments:

1/ For end users who require the choice of customising the verification report, there are a couple of options. A very basic option is to amend the Printer Header field in the Printing tab of the Setup window. However, the option which offers the most flexibility is to extract the required verification data from a csv file. This will involve some further development from the user, but the Axicon Verifier software gives the option to save data automatically in a csv file which can then be the base for editing a customised verification report template.

2/ To preview the verification report, press on "ALT + SHIFT + F7", the empty "Test" window will pop up, then click on the print option from the "Command" window, click OK and the printout content will appear in the test window.

6. Maintenance

6.1 - Basic Verifier maintenance

1. Your Axicon verifier is a piece of high precision quality control equipment and should be handled with due care. Try to keep the verifier as much as possible away from dust, as particles could accumulate and affect the verifier optics.

2. Please retain the plastic transit case. Should you need to return the unit to Axicon, this case (plus appropriate packaging) will protect the equipment in transit.

3. Only use power and data cables supplied by Axicon. Use of non-approved accessories will invalidate the warranty.

4. If the verifier is dropped or subject to similar misuse, the accuracy of the results may be affected. The unit should be returned to Axicon immediately for servicing.

5. As the owner of an Axicon Verifier you are entitled to free software updates for life. The latest copy of the software is always posted on our website (www.axicon.com). Please check the website on a regular basis for the latest upgrades. Software updates can cover minor changes, bug fixes or can include updates to respond to changes in the specifications, so upgrading your Axicon Verifier software on a regular basis is a necessary part of the maintenance procedure of your Axicon verifier. Changes to the software are documented in a text file that can be downloaded from the Download page of our website.

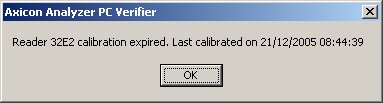

6-2: Calibration Card Maintenance

The Axicon calibration card that was delivered with your equipment is guaranteed for one year, but if handled with care and protected from prolonged direct exposure to light, its properties should not be affected and it should remain accurate. We recommend that you keep the calibration card in a dry and dark environment andin a place accessible to the users that have been trained and authorised to perform the required regular calibrations.

If you believe that the calibration card properties might have deteriorated (bent, fading, visible dirt) or if you are concerned that the guarantee expiry date has expired, we recommend that you order a fresh calibration card from your Axicon reseller.

Comments:

| Axicon have always produced calibration cards for their verifiers using their own in-house photoplotting and photographic systems. The purpose of calibration of a printed symbol verifier is to teach it what a reference white reflectance and a reference black reflectance actually are. For this reason it is important to use materials which give as consistent a diffuse reflectance as possible and matt finish photographic papers are ideal for this. The bar code image that is printed on the cards is of less importance in that any scannable bar code will enable the calibration process to work but it is obviously preferable to have appropriate bar code symbols of a reasonable quality. As from the first quarter of 2006, Axicon has commenced supplying new calibration cards which for the first time are not manufactured in-house. The company that we are using to source these from currently produces the bar code world's standard reference symbols. The material used for our new Calibration cards will be identical to the material which they have used to produce the UCC (GS1 US) Conformance Test Cards. Axicon will therefore provide cards of the same quality as those Conformance Test cards in terms of their reflectance consistency and bar code quality. |

|

The design has changed from our previous calibration cards and the new card now contains examples of the main GS1 symbologies which the Axicon verifiers can verify including some example RSS bar codes but as mentioned before it does not matter which bar code symbol is used for the calibration process as long as the verifier is actually able to read it.

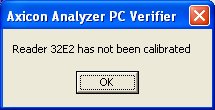

6-3 - Recommended Maintenance Procedure: The Factory Recalibration

Axicon equipment is designed and manufactured to the highest specifications and complies with all relevant international standards. Barcode verifiers are precision measuring and testing devices. It is normal practice for all inspection, measuring and test equipment to be regularly checked and recalibrated – and a precision quality control instrument such as a barcode verifier is no exception.

To ensure that your equipment is working correctly, we recommend that you return your verifier annually to Axicon for servicing / factory recalibration (please note that a factory recalibration is different to the user calibration procedure as explained above). Please contact Axicon (or your approved Axicon reseller) for further details of this service. This service is called a Verifier Calibration & Service (VCAS). On top of a factory calibration, this service also includes a check of the cables and LEDs, cleaning of the unit, supply of a fresh calibration sheet and recertification of the unit.

6-4 - Procedure to follow if you think your Axicon verifier is not working correctly

If you think that your Axicon verifier is faulty and could give inaccurate results then the first step is to contact your Axicon reseller's technical support department and describe in as many details as possible what the problem is. Many problems are often solved at this stage. Depending on the circumstances, here are some general recommendations.

-

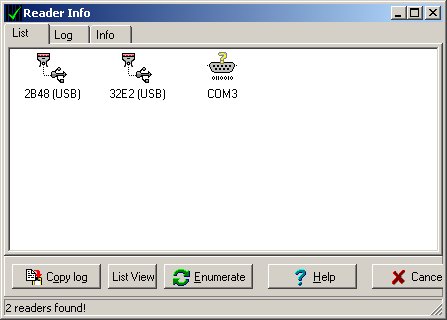

You can't get the verifier to work at all after installation: On an USB connection there is a chance that the drivers have not been installed properly. See the installation instruction paragraph for more information. On a serial connection, try activating the verifier from the Reader Info window. If this fails, try another port or even use another PC to check whether the problem relates to the verifier or the initial PC it had been installed on.

-

The verifier suddenly stops working after previously working correctly for a period of time. Possibly the verifier has not been recognised by the software and you should go into the reader info window to try activating it or perhaps the cable has been damaged or has developed a fault, in which case the unit might work intermittently or not at all. Contact you reseller for a spare cable or try connecting to another PC to identify if the problem is PC related.

-

The verifier works but you think that its accuracy might have been affected. This could happen because the verifier has been mishandled, because it has been used for a long period of time without being factory calibrated, because it has been exposed to dust, dirt or extreme conditions or simply because the results you get do not make sense to you, e.g you get very low grades on the calibration sheet barcodes. Please bear in mind that we often have cases where a user may believe that the verifier is not providing accurate results, when it has actually been the case that it had been badly operated or that the scanned barcode is actually very poor or inconsistent and prone to give inaccurate results. Regardless of whether you are confident or just suspicious that you have an issue with your verifier, you do have ways to check the verifier's accuracy and its conformance to the industry standards.

To check the accuracy of a verifier, it is important to check it against known values. The calibration card that has been supplied with the equipment is surely the best sample to scan because it will give consistent results, however, other than Rmax and Rmin, no other values of the ISO grading of the codes are known. Unless you have proceeded to an ISO grading on the calibration sheet barcodes when you first received your verifier, just after calibration and kept a copy of the verification report you will have nothing to compare with when you want to check accuracy at a later stage. The ultimate reference remains the Calibration Standard Conformance Test Cards supplied by GS1. These cards have been manufactured under very stringent conditions and their accuracy has been tested individually. The values for a set of measurable ISO/ANSI parameters are specified, and the card can thus be used to check that the results you get using your verifier are within the tolerance values specified in the ISO 15426 Standard.

Another test you can perform is to check the uniformity of the profile to identify any abnormal fade in one or more of the LEDs or to identify potential dirt spots on the optics of the verifier. To do so, scan a plain white sheet of paper (the back of the calibration card for example). From the Reflectance Profile Window, by ticking the "Display static reflectance" box, you can then check the shape of the reflectance signal you receive from your verifier. It should be in the shape of an horizontal line. If not, then please make a copy of the profile to show it to your Axicon reseller's technical support department.

6-5 - Return to base procedure.

If the verifier needs to be returned to your Axicon reseller for maintenance or repair, please pack the verifier and all cables in the original Axicon carry case. It is also mandatory to include in the package an official Axicon RMA form, with your contact details, the equipment serial number and details on what is wrong or the selected type of service that has to be performed. Prior to this, we recommend that you contact your Axicon reseller to give further notice of the return of the unit and to obtain a quotation for the service required.

DISCLAIMER

This document is intended as a recommendation of work practices sponsored by Axicon Auto ID Ltd. Whilst this document is believed to contain correct information, neither Axicon Auto ID Ltd nor any of it’s associated companies, nor any of it’s employees, make any warranty, express or implied, or assume any legal responsibility for the accuracy, completeness or usefulness of such information that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by its trade name, trademark, manufacturer or otherwise, does not necessarily constitute nor imply Axicon Auto ID Ltd endorsement nor recommendation. The views and opinions of authors expressed herein do not necessarily state or reflect those of Axicon Auto ID Ltd.